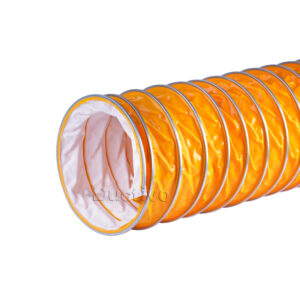

Flexible Hose

Introduction to Flexible Hose

Diameters Available for Flexible Hose

Ductivo offers a wide range of flexible air hose diameters to meet diverse project needs. Depending on the material and application, you can get flex air hoses in sizes ranging from 1 inch to an impressive 86 inches. This variety makes it easy to find the perfect fit for your specific air duct or ventilation system. Whether you’re working on a small-scale project or a large industrial setup, Ductivo’s flexible air hoses provide excellent performance and durability. With these flexible options, you can optimize air distribution and ensure efficient airflow in any environment. No matter the project size, Ductivo has the right flex air hose to suit your requirements, delivering high-quality and reliable solutions every time.

Standard Length of Flexible Hose

Ductivo’s flexible air hoses are typically available in standard 25-foot lengths, ideal for most air handling and ventilation projects. These lengths provide enough flexibility and reach to suit common installation needs. However, Ductivo goes beyond the standard, offering custom lengths for specialized projects. If your project requires longer flex air hoses, Ductivo can accommodate with higher lengths to ensure maximum convenience and efficiency. Whether you’re working on a large commercial system or a unique ventilation setup, Ductivo’s flexible air hoses deliver reliable performance tailored to your specific requirements. The ability to customize hose lengths ensures you get the perfect solution for your airflow needs.

Thicknesses Available for Flexible Hose

Operating Temperature Range of Flexible Hose

The operating temperature range of Ductivo flexible hoses varies based on the type and material used in their construction. Each flexible duct hose is designed to withstand specific temperatures, ensuring optimal performance in different environments. For example, high-temperature applications require materials that resist heat, while other hoses may need to function in cooler conditions. Choosing the best flexible hose for your project involves considering both the operating temperature and the durability of the material. With the right selection, you can ensure efficient airflow, long-term functionality, and enhanced safety, regardless of the temperature conditions.

Applications of Flexible Hose

Flexible hoses are essential in various industries due to their adaptability, diverse types, and range of thicknesses and diameters. The specific characteristics of each flexible hose make them suitable for many applications, ensuring performance across different conditions.

Here are some common uses of flexible hoses:

- Industrial ventilation: High-thickness flexible exhaust hoses are ideal for ventilating hot, humid, and polluted air in industrial settings.

- Air conditioning systems: PVC flexible hoses are frequently used in home and commercial air conditioning systems to transport clean air.

- Material transfer in production lines: Transparent flexible metal hoses allow visibility of materials being transferred, making them ideal for production lines.

- Ventilation of industrial kitchens: Heat-resistant flexible air hoses release steam and smoke from large, industrial kitchens efficiently.

- Split duct systems: These hoses are used in split ducts due to their flexibility and resistance to wear and tear.

- Transferring hot and cold air: Silicone-coated flex air hoses can withstand extreme temperatures and are used for transferring both hot and cold air.

- Air filter systems: Factories and workshops utilize flexible metal hoses for air filtration in various environments.

- Evacuation of toxic gases: In industrial environments, durable flexible exhaust hoses transport hazardous gases safely.

- Moisture and steam evacuation systems: High-flexibility flexible hoses are effective for evacuating moisture and steam from confined spaces.

The wide variety of applications demonstrates the critical role of flexible air hoses in different industries. Their ability to adapt to diverse conditions and materials makes them indispensable for both residential and industrial projects.

Advantages And Disadvantages of Flexible Hose

Advantages

The flexible hose offers numerous advantages, making it a popular choice in various industries and applications. Its unique characteristics provide flexibility, durability, and efficiency, ideal for both residential and industrial use.

Here are the key advantages of flexible hoses:

- High acceptability: The flexible air hose can easily be installed in complex and tight routes, thanks to its flexible design, making it suitable for a wide range of challenging applications.

- Lightweight: Compared to other ductwork options, flexible hose pipe weigh less, making installation quicker and easier. This eliminates the need for heavy structural support during installation.

- Corrosion resistance: Made from durable materials, flexible metal hoses are resistant to rust and corrosion, ensuring long-lasting performance in harsh environments.

- Economical price: The flexible air hose is often more cost-effective than other available alternatives, offering an affordable solution without compromising on quality.

- Resistance to heat and humidity: The flexible exhaust hose can withstand high temperatures and humid conditions, making it ideal for use in hot and humid environments.

- Sound reduction: These hoses help reduce noise transmission in HVAC systems, creating a quieter operation in air transfer applications.

- Easy installation: The compact and lightweight nature of the flexible hose pipe makes it easy to install, reducing both labor time and costs.

- Resistance to breakage: Designed to handle mechanical pressure, flexible metal hoses are highly resistant to breakage, providing durability in demanding conditions.

Thanks to these advantages, flexible air hoses are the perfect choice for air transfer, ventilation, and filtering in both industrial and domestic settings. Their versatile nature makes them an essential component in a wide variety of projects.

Disadvantages

Additional Explanations