We know that many tools and accessories are used to connect the ventilation channels. To connect two round channels to each other or to connect a side piece to the spiral channel, you can use the round channel connector and tighten it with an automatic screw, or make this connection with the help of a round flange. Round flanges are all made and produced with a round flange machine.

A round flange is actually a corner that is rounded and has a number of holes on its outer edge. This part is placed from the outside around the round channel or the spiral channel, half a centimeter from the edge of the channel, it goes back on the flange, and this makes the flange not separate from the part. Self-tapping screws are also used to fasten these parts to each other. Two round flanges are used to connect both parts, which are placed on both sides of the connection.

What is the use of flange?

The flange is used to connect two pieces of the channel to each other. as we know ; There are other connection methods that do not require a flange and can be done without it. But it is necessary to know that the use of flanges in the place of connections will prevent the loss of energy to a great extent, and in this way, the pipe can be sealed at the place where the two parts are connected. which will significantly increase its strength and resistance.

The form of connecting two channels to each other can specify the type of connection used. In cases where two spiral channels are connected to each other, a flange is used more than an interface and in connecting side parts such as three-way, four-way, knee, etc. to the spiral channel. Square flanges are also used in the design of square channels, but this machine is used to produce round flanges.

Other types of flanges, such as square and polygonal flanges, have their own uses as well as round flanges. But in general, it can be said that increasing the resistance and strength of channeling work as well as preventing energy loss is the general property and characteristic of all different types of flanges.

Important points in buying a round flange

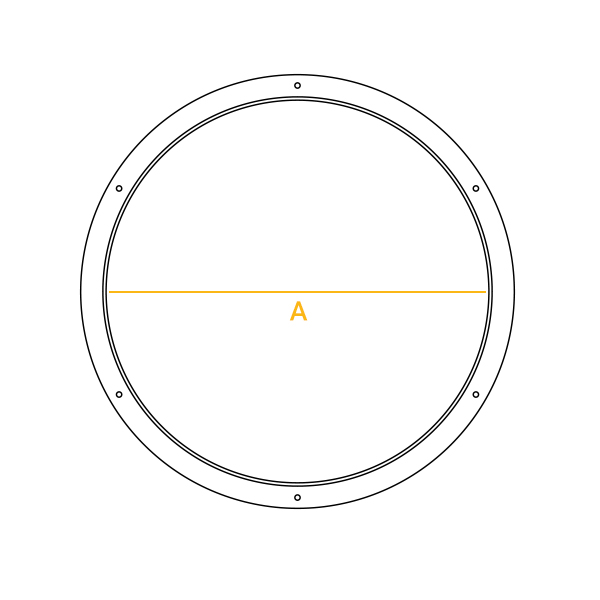

The flange is considered as an intermediary part and an interface. And in all cases, the size, length, material and thickness of its opening should be considered in order to be placed at the connection point.

For example, one of the things that should be kept in mind when entering the width and thickness of the work edges; The indentation is the edge of the flange. Because during the installation and positioning of the flange at the joint, the edges of the channel turn on the flange and inward. Therefore, by turning the edges of the channel on the flange, the piece can be fixed in place so that it does not move down or up the channel.

The installation of screws on the flange during construction will ensure that the part is completely fixed in its place during placement. What is considered to increase the quality of bending and rolling operations in the manufacture of all flanges; It is related to the production mechanism and round flange manufacturing device, which will ultimately lead to increased performance and ease of installation at the junction of two channels.

For example, the edges of the flange during construction are necessary so that it is not too open so that the flange can be easily raised and lowered, or it is not too closed and small so that it is difficult to move it for installation.

In the meantime, there is also the possibility that issues such as the instability of the flange at the joint, improper sealing, air or water leaking out of the pipe, etc. may occur. But by making flanges based on standard values, such problems can be avoided.

It is necessary that the weight of the flange does not increase the weight of the channel. Otherwise, additional load should be applied to the supports. Imagine, in addition to the heavy weight of some channels that are used for the ducting and ducting system of a building; Parts and other connections also take a lot of weight.

Quick and easy installation of round flanges is another important issue; which by considering the standard sizes and also entering the right and basic parameters can lead to the production of a round flange with the right size and standard edges.

Related products

-

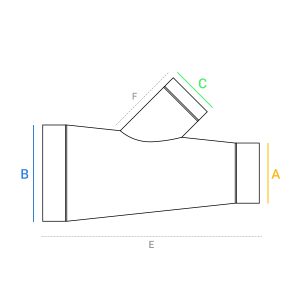

Reducing Tee 45

0 out of 51.00 $ Inquiry This product has multiple variants. The options may be chosen on the product page -

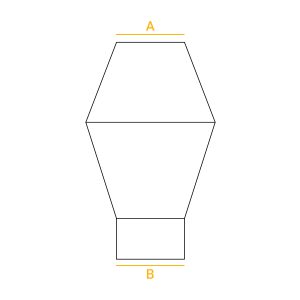

Hat

0 out of 51.00 $ Inquiry This product has multiple variants. The options may be chosen on the product page -

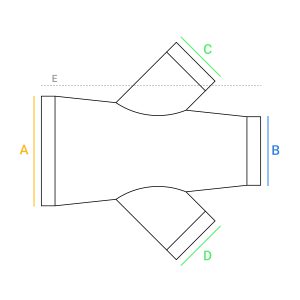

Reducing Cross 45

0 out of 51.00 $ Inquiry This product has multiple variants. The options may be chosen on the product page -

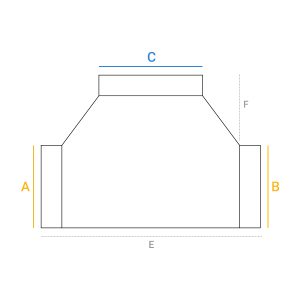

TC Tee

0 out of 51.00 $ Inquiry

Reviews

There are no reviews yet.