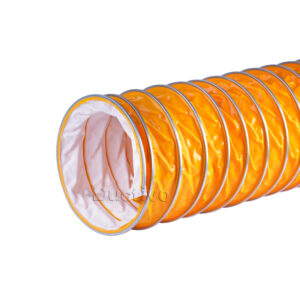

PU flexible hose is composed of a layer made from a strip of metal-coated polyurethane. This Flexible Hose is manufactured in diameters of 3, 4, 5, 6, 7, 8, 9, 10, 12, 15, 18, 20, 22, 25, 30, 35, 40, 45, 50, 55, 60, 65, 70, 75, 80, and 90 centimeters, with branch lengths of 6 meters. This hose is highly flexible, meaning that it can easily be shaped and molded, even with the help of manual force. The body of this hose is a single unit, and its surface and inner layers have been designed and produced in a way that eliminates any gaps or seams, preventing the infiltration of any substances and ensuring high resistance.

Due to its excellent abrasion resistance, the PU hose is primarily used for transporting powders. It finds application in industries such as pharmaceuticals for material transfer, woodworking and MDF industries for transporting sawdust, agricultural and livestock industries for conveying straw and similar materials, as well as foam industries.

Diameters Available for Production

Ductivo offers a broad range of diameters for PU suction hoses, specifically in 2, 3, 4, 5, 6, 8, 10, 12, 14, 16, and 18 inches. This variety ensures that specific customer needs can be met, with customizations available in wall thickness as well.

The Standard Length of Each Hose

Each Ductivo hose is typically manufactured in a standard length of 25 feet, although custom lengths can be produced to meet individual specifications.

Operating Temperature Range

PU flexible hoses can operate within a temperature range from -40°F to +194°F, accommodating a variety of environmental conditions without compromising performance.

Applications of Ductivo PU Flexible Hoses

PU hoses are extensively used across various sectors, including mechanical and plant engineering, as well as municipal and cleaning technology. Their robustness makes them particularly effective for the suction of abrasive solids such as dusts, powders, fibers, chips, granulates, and coarse-grained particles, along with liquids and gaseous media.

Industrial Usage

- Food and Beverage Industry

- Pharmaceutical Industry

- Dairy Industry

- Brewing and Beverage Industry

- Cosmetics and Personal Care Industry

- Confectionery Industry

- Catering and Hospitality

- Chemical Industry (Certain Applications)

- Aquaculture and Fishing

- Agriculture (Certain Applications)

Advantages and Disadvantages

Polyurethane hoses offer significant advantages over traditional hoses. They are lighter, more resistant to abrasion, chemicals, and temperature variations—key attributes for harsh industrial environments like construction sites and manufacturing plants. While the initial cost of PU hoses may be higher compared to rubber hoses, their extended durability and reduced maintenance needs often result in long-term cost savings.

Polyurethane Industrial Hose Features

- High resistance against abrasion

- Resistance against impacts, pressure, tension, tearing, decay, and corrosion

- Endurance under environmental conditions like wind and rain, cold and heat, humidity, heat, fire, and direct sunlight radiation

- Resilience against chemical and toxic factors such as gases and toxic liquids, gasoline, oil, and diesel

- Long lifespan

- PVC free

- Phthalate free

- High flow rate

- Long shelf life

- Gas and liquid tight

- Chemical resistance

- B1 class fire resistant (only 0.5 – 1.00 mm thickness range)

- Clean core tubes (non-contaminating)

- High elasticity over the entire hardness range

- Excellent resistance to oils, grease and many solvents

- Superior abrasion resistance

The wall of the product is composed of Thermoplastic ester based PU material with a range of thicknesses available: 0.4 mm, 0.5 mm, 0.7 mm, and 1.0 mm and Each thickness is suggested for specific usage. It has a transparent color and exhibits abrasion resistance according to ISO 4649 standards, with a range of 30 to 40 mm³. The wire used in the construction is coated spring steel wire, and it comes in a diameter range (Ø) of 30 mm to 500 mm. The wall is designed to operate within a temperature range of -40 °C to +90 °C, with short-term usage possible at 125 °C (tested for 4 hours). The standard lengths available are 6 meters and 10 meters. For packaging, it is enclosed in a transparent plastic bag. The product holds DIN 4102-B1 certification for thicknesses ranging from 0.5 mm to 1.00 mm.

This product is produced by 100% thermoplastic polyester polyurethane and reinforced by high tension coated steel wire. There are four different types of thickness for various applications.

Introducing Ductivo PU Flexible Hose

PU flexible hoses, also known as polyurethane suction hoses, are celebrated for their exceptional durability and flexibility. Made from the advanced polymer material polyurethane, these hoses boast superior elasticity and resistance to abrasion, making them ideal for a wide range of industrial and commercial applications. Ductivo’s product line includes various specialized models such as standard suction hoses, microbe-resistant suction hoses, food-safe suction hoses, electrically conductive suction hoses, antistatic suction hoses, and flame-resistant suction hoses. Each model is designed to meet specific industry requirements, ensuring optimal performance in demanding environments.

PU Flexible Ducting Hose

Polyurethane (PU) flexible ducting hoses excel in various demanding applications due to their superior durability, flexibility, and resistance to wear and tear. These hoses are particularly effective in systems requiring industrial ventilation, dust collection, and fume extraction. Their resistance to chemicals, moisture, and UV radiation makes them a durable option for harsh environments, ensuring long-lasting performance in industrial settings.

2 Inch Flexible Hose

A 2 inch flexible hose is essential for applications where space is at a premium but efficient air movement is necessary. This hose size is perfect for HVAC systems in residential buildings and for dust extraction in small industrial workshops. Its compact diameter allows it to easily fit into tight spaces, making it an indispensable tool for maintaining air quality and system efficiency.

3 Inch Flexible Hose

The 3 inch flexible hose is a versatile component used across various sectors, particularly in automotive and woodworking applications, as well as for agricultural purposes like grain transfer. Its size provides an excellent balance between the need for easy handling and the ability to move a significant volume of air or materials, making it ideal for medium-scale industrial and agricultural operations.

9 Inch Flexible Duct

The 9 inch flexible duct is critical for large-scale applications such as air handling and ventilation in commercial and industrial buildings. It is designed to handle high volumes of air, making it an essential part of maintaining environmental standards and air quality in large spaces such as warehouses, factories, and large retail environments. Its robust construction ensures durability and reliability even under strenuous use.

Vacuum Flexible Hose

Vacuum flexible hoses are crucial for effective cleaning in both residential and industrial vacuum systems. These hoses are built to withstand high suction pressures and are capable of transporting various types of debris, from fine dust to larger particles. Their design ensures compatibility with a wide range of vacuum cleaners, enhancing the overall efficiency and effectiveness of cleaning operations.

Conclusion

PU flexible hoses are an excellent investment for various industrial applications, combining durability, flexibility, and resistance to harsh conditions. Their range of specialized models and customizable dimensions cater to a diverse set of industrial needs, making them a preferred choice for businesses seeking reliability and cost-effectiveness.

To fix a leak in a flexible hose, first identify the source of the leak. If the leak is at a connection point, try tightening the connection with a wrench. If the hose itself is damaged, apply waterproof tape or a hose repair tape specifically designed for such repairs over the leak area. For more severe damage, replacing the section of the hose or the entire hose might be necessary.

Fixing a flexible hose involves determining the nature of the problem. If it’s a small hole or tear, using a hose repair kit or sealing it with silicone tape can be effective. For issues with connectors or fittings, ensure they are tightened or replaced as needed. If the damage is extensive, consider replacing the hose.

Related products

-

Spiral lock flexible hose

0 out of 5Inquiry -

PVC flexible hose

0 out of 51.00 $ Inquiry This product has multiple variants. The options may be chosen on the product page -

Canvas Air Hose

0 out of 5Inquiry -

Semi-Rigid Aluminum Duct

0 out of 51.00 $ Inquiry This product has multiple variants. The options may be chosen on the product page

Reviews

There are no reviews yet.